ATTENTION TO DETAIL IS THE KEY TO SUCCESS

The exploration of the Moon’s South Pole holds the promise of scientific discoveries, resource utilization, and the establishment of a sustainable human presence on the Moon. A comprehensive understanding of the environmental conditions is essential and will significantly impact the planning and execution of lunar missions.

Enovus Labs have conducted extensive literature reviews and in-depth data analysis to ensure that our thermal models accurately predict the environment at any location on the Moon's surface.

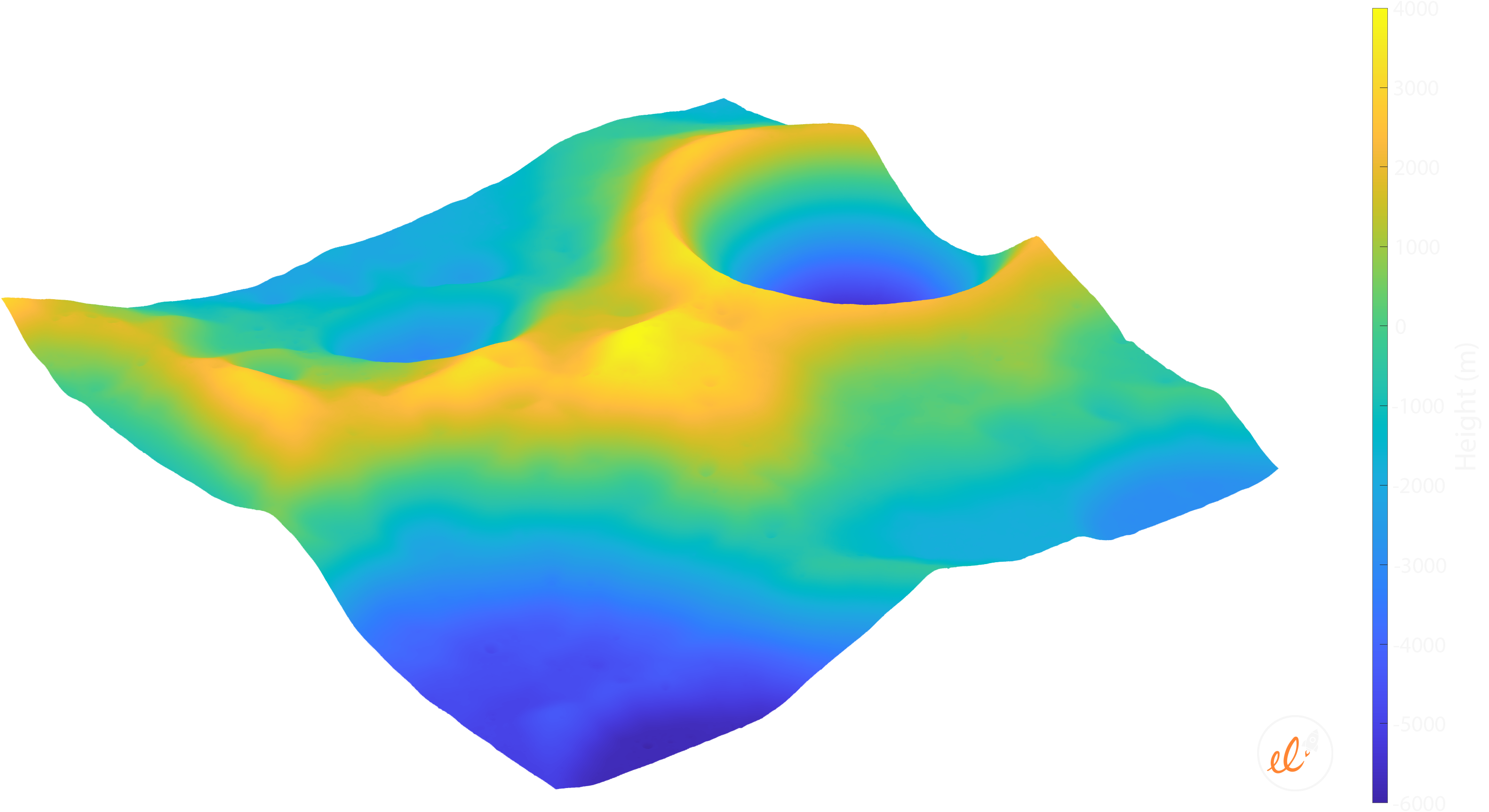

Understanding the effects of the lunar terrain and material properties through existing literature is the first step in any thermal analysis. The distribution of sunlight, the thermal characteristics of surface materials, and the existence of shadowed regions all contribute significantly to the prediction of temperature variations across the lunar surface.

To guarantee the precision of our thermal models, we cross-reference our findings with data available in the literature and experimental data recorded by the Lunar Reconnaissance Orbiter (LRO). This approach enables us to construct a model that truly builds upon prior work, empowering us to design superior devices compared to those developed previously.

The thermal and terrain data was recorded by the LRO, and the raw source data can be found here and here.

Our thermal models meticulously consider all aspects of the challenging lunar environment right down to sub-surface soil properties. This enables us to optimize thermal solutions tailored to specific missions.

Inaccurate models can lead to two outcomes:

Our precision engineered thermal models have the potential to save you millions, first time.

Beyond thermal considerations, extensive mechanical engineering is essential for space-deployed hardware due to the intense stresses during launch/landing, including vibrations and shocks, which necessitate meticulous engineering to prevent failures. Additionally, the impossibility of repairs in space means hardware must be highly reliable. At Enovus Labs, we excel in designing innovative components that are both lightweight and high-performing to meet strict weight and size constraints. Ultimately, the success of any space mission heavily depends on the performance of its hardware, making it crucial that experienced and skilled engineers like us are at the core of any project team.

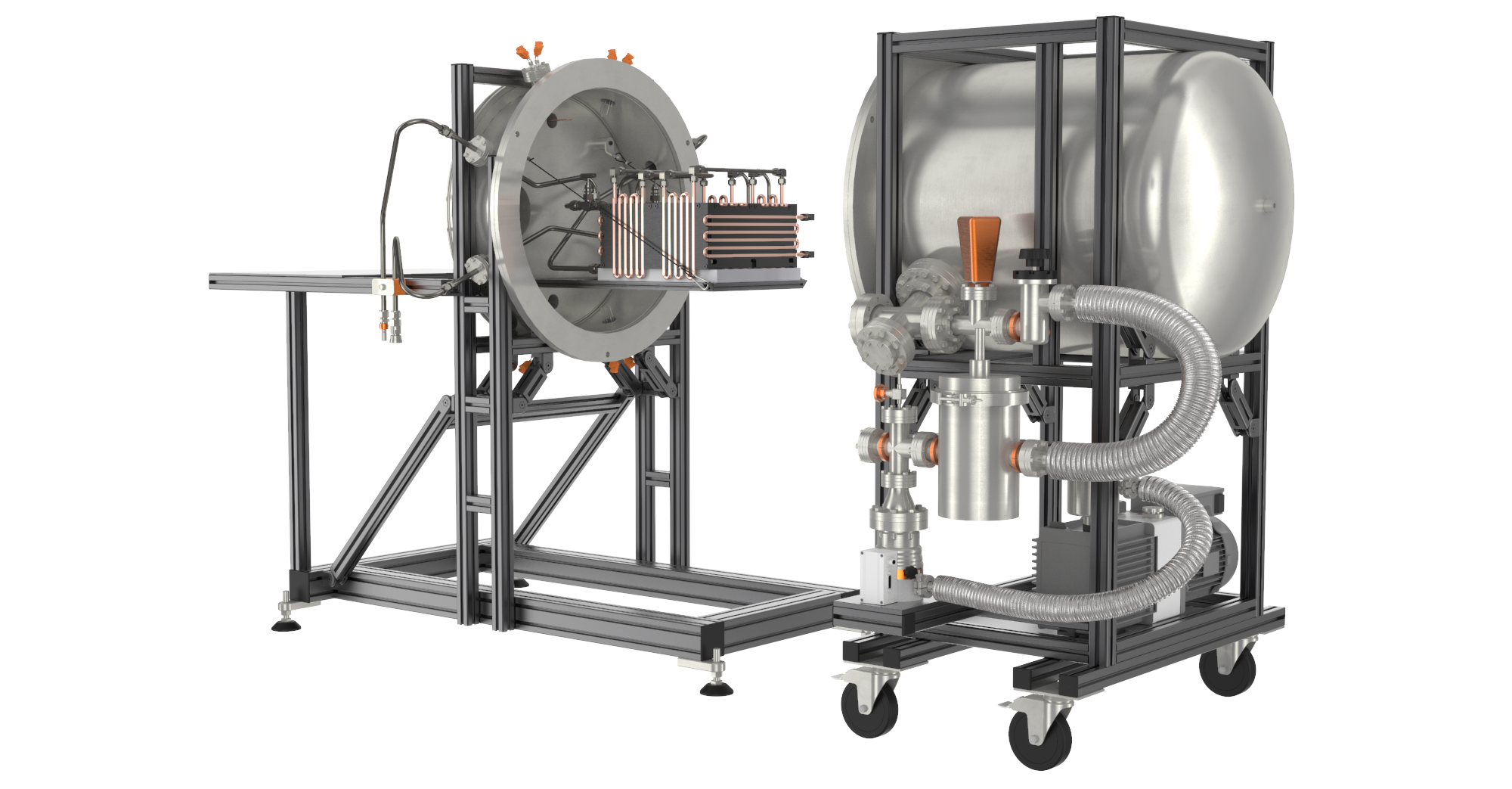

The experimental validation of our thermal models is of paramount importance, and to facilitate this, we have built a state-of-the-art Thermal Vacuum (TVAC) chamber. This hardware testing facility allows us to rapidly evolve our designs, in-house. Additionally, we conduct comprehensive mechanical engineering design, incorporating Finite Element Analysis (FEA). Our shock and vibration test bed further allows us to experimentally validate our FEA models quickly.

These micro design iterations save considerable time and money by serving as a proactive measure against potential failures during the more costly large-scale qualification testing.

Details of our TVAC chamber can be found here.